Dynaburrs

Carbide rotary burrs are ideal to cut, shape, grind and remove sharp edges, burrs and unwanted material.

Carbide rotary burrs are ideal to cut, shape, grind and remove sharp edges, burrs and unwanted material. DynaburrTM tungsten carbide burrs work with Dynabrade pencil grinders and die grinders.

Key-surface for Dynaburr Carbide Burrs

Tungsten carbide burrs can be used with a variety of materials including steel, stainless steel, aluminum, cast iron, exotic alloys, precious metals, ceramics and composites, non-ferrous metals and wood.

Key-market for DynaBurr Tungsten Carbide Burrs

Transportation – Aerospace, Rail, Marine and Automotive; Metalworking and Metal Fabrication – Welding, Tool and Die, Castings and Foundries; Energy – Oil and Gas, Wind Turbine.

Applications

All DynaBurr’s are double cut style and are ideal for medium to light stock removal, chamfering, deburring, weld removal and blending, creating radii, precise finishing, polishing and for removal of parting lines and flash.

Features and benefits

DynaBurr tungsten carbide burrs provide significantly longer life than high speed steel burrs.

Available in 3 mm and 6 mm metric shanks and 1/8" and 1/4" shank sizes.

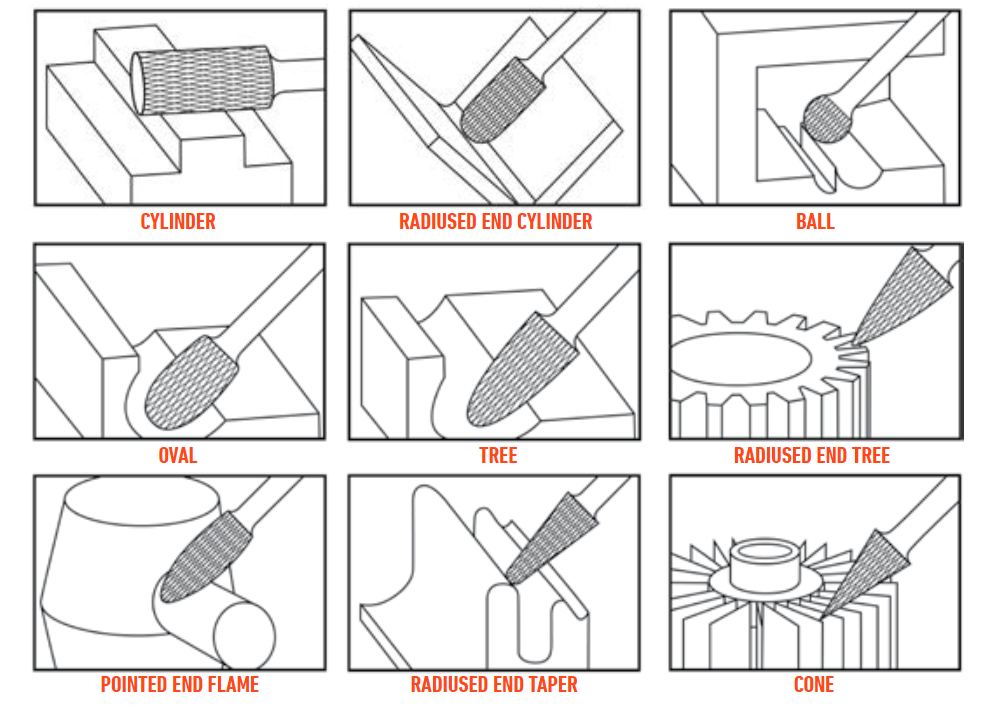

Shapes

DynaBurrTM carbide burrs are offered in the most common shapes including Cylinder, Radius End Cylinder, Ball, Cone, Inverted Cone, Tree and Flame to cover a broad range of applications and surface profiles.

Tips and Techniques

For maximizing performance safety, please:

- Apply light pressure and let the burr do the work.

- Keep the carbide burr moving along the surface to avoid gouging and digging causing a rough surface.

- Try to end on an up stroke to generate smoother finishes.

- Ensure burr is inserted into the collet and clamped down tightly.

- Work on the highest material first and use light pressure while keeping the burr moving.

- Make sure the work piece or surface is secure.

- Avoid jamming burr into the work piece.