What is the best speed for your drilling application?

Find out in this blog post our recommendation chart on drilling speeds and how to get the best result per surface in the shortest time using high speed steel (HSS) drills.

Dynabrade drills are high quality tools for industrial and professional use in a variety of industrial applications. They have been designed to provide exceptional power, precision and durability. They are available in a variety of models and sizes to meet the specific needs of each user. You can find all of our models here.

These include right angle drills, straight-line drills, side handle drills and vacuum models. Each type of drill is designed for specific tasks and offers features to make drilling easier. Dynabrade drills are also known for their ergonomic design and low vibration level, making them more comfortable to use for long periods of time.

Why do you need to follow the recommended speeds when using Drills?

Adhering to the recommended drill speeds for the application area is essential for a good reason: it ensures optimal results in terms of accuracy, quality and tool durability.

When the drill speed is too high for the surface, it can cause damage to the material, such as cracking, splintering or warping. But not only that.

In addition to degrading the application surface, it can lead to overheating of the tool, premature wear of drills and accessories leading to loss of accuracy.

On the other hand, if the speed of rotation is too low, it will reduce the efficiency of the drill and increase the time required to complete the task, premature wear of the tool, and costs. Dynabrade solutions are optimized to improve performance and reduce costs.

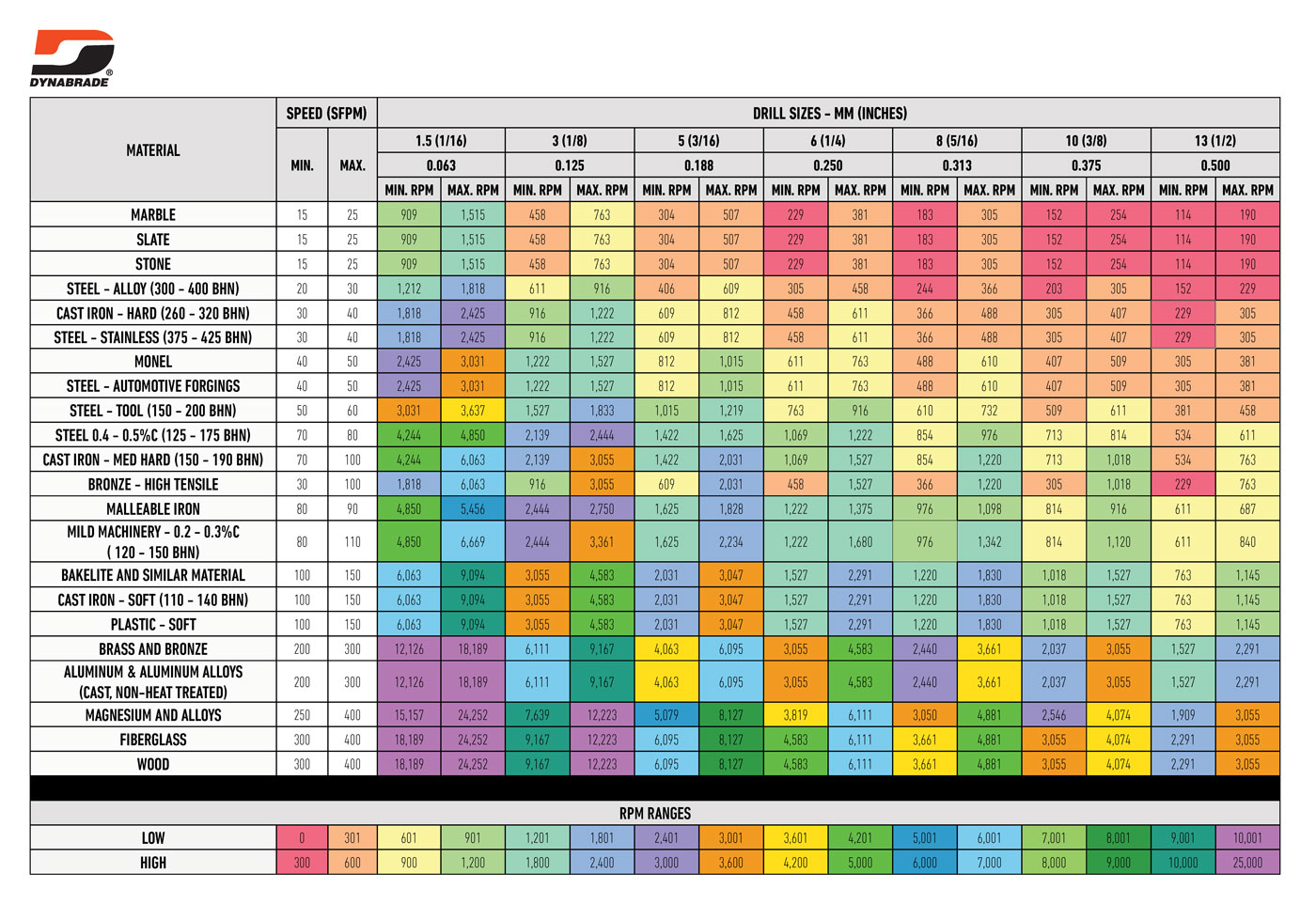

Dynabrade recommends specific speeds for different materials and drill diameters. These recommendations are based on testing and experience to ensure the best possible results. Here is our chart:

Dynabrade drills are high quality professional tools designed to provide exceptional power, precision and durability. They are ideal for use in challenging industrial environments.

But following the recommended drill speeds for the application areas will help extend the life of the tool, achieve superior results, and work more efficiently. That's why it's important to always follow the manufacturer's speed recommendations.