Save energy with Dynabrade!

Save energy, improve your efficiency and safety and

reduce cost using Dynabrade Solutions!

In recent years, as the world faces increasing energy demand and limited resources, energy conservation has become an important issue.

The need to reduce energy consumption is becoming extremely important not only for environmental reasons, but also for economic and sustainability reasons. Energy saving measures help reduce energy consumption, lower energy costs, and reduce greenhouse gas emissions.

By taking action to save energy, businesses can contribute to a more sustainable future and ensure a reliable and affordable energy supply for future generations. Most importantly, they can save money while increasing the productivity and improving the safety of their employees.

There are many ways to save energy, such as making fast and simple behavior changes, using energy-efficient products, and adopting innovative technologies. With the right approach and commitment, saving energy can help create a better future but also increase the profitability of your business. This is where Dynabrade comes in.

The benefits of Pneumatic Tools

If you are using pneumatic tools, you should know they offer a wide range of benefits to users, making them a popular choice in many industries:

- One of the main benefits of using pneumatic tools is their efficiency. Pneumatic tools are powered by compressed air, which allows them to perform tasks quickly and effectively. This can save time and increase productivity, especially when compared to electrical tools.

- Pneumatic tools are also known for their durability and reliability. They can last longer and require less maintenance than other types of tools. Another advantage of pneumatic tools is their versatility.

- There is a wide range of pneumatic tools available for different applications, such as drilling, grinding, sanding, and more, making them a suitable choice for many different tasks.

- Pneumatic tools are also generally easier to use than other types of tools, with many requiring only a single hand to operate. Furthermore, pneumatic tools are often lighter than their electrical or manual counterparts, making them more comfortable to use for extended periods of time.

These benefits, combined with their affordability and safety features, make pneumatic tools a smart choice for businesses looking to improve their efficiency, productivity, and overall performance.

Your compressed air network might be a huge issue!

Compressed air leaks can be a major source of waste and inefficiency in compressed air systems, and can result in significant financial losses for businesses. Here are some reasons why compressed air leaks can be so costly:

- Energy waste: Compressed air leaks allow valuable compressed air to escape, wasting energy and increasing operating costs.

- Decreased system efficiency: Leaks reduce the overall efficiency of a compressed air system, requiring more energy to produce the same amount of air flow.

- Increased energy costs: Compressed air is a major source of energy consumption, and leaks can result in increased energy costs, especially over time.

- Maintenance costs: Leaks can cause damage to other components in a compressed air system, requiring expensive repairs and maintenance.

We will explain you later how to optimize your system. This might help you divide your cost by 20 to 30%!

Where do the leakages come from?

Two of the most common sources of leakages in a compressed air network are:

- Poor connections between couplers, nipples and the hoses

- Couplers and nipples made in unsustainable materials such brass or plastic which cause wear and leak

75% of leaks come solely from poor-quality couplings and hoses!

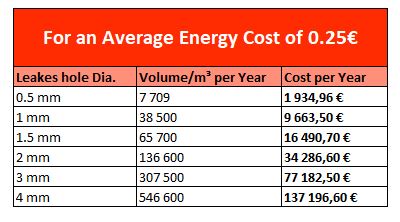

Let's look at the numbers

If there is one thing you need to remember, it is this one: Compressed air leaks cost you every second, minute, and hour of the year.

Should you change your complete Compressed Air Network?

Absolutely not.

Some cost-effective measures are enough to help you reduce the risk of leaks in your compressed air system, minimize energy consumption, and save money on operating costs.

And it's as easy as changing a light bulb!

Take control now of your Compressed Air Network with Dynabrade!

Installing high quality components from the start will save you a lot of energy and therefore money, and ensure a safe working environment for your operators.

A one millimeter hole costs hundreds or even thousands of euros every year. You may not even know it, but a compressor has to do a lot more work to provide enough air to tools when there are leaks.

And that's where you start losing money. In general, a compressor produces between 20 and 30% more compressed air to compensate for air leaks. This is the case for 80% of industrial installations.

So imagine replacing your couplers, plugs or stream line connectors? In addition to the considerable savings, these changes create a safer and more efficient working environment.

You can expect a return on investment after 3 to 6 months with our Solutions!

Discover Dynabrade Solutions

- Highly durable: To ensure a long service life, Dynabrade Air Line Assemblies are intended to endure severe handling in difficult working situations. They are exceptionally resistant to collision, vibration, and swiveling.

- Leak-free and energy-saving: Our Couplers do not leak. There is no superfluous air loss between the Coupler and the Tool, and the compressor is not forced to compensate for air leakage. They also offer the highest flow rate on the market for quick attach couplings! Because of the high flow and low pressure drop, the connection requires less compressed air and allows the compressor to be adjusted at a lower pressure. When these two advantages are combined, they result in decreased manufacturing time and higher efficiency.

- Optimize for Safety: In compliance with ISO 4414, Dynabrade safety couplings have a vented safety feature. This allows the flow pressure to be released prior to disconnection, which reduces noise and eliminates the possibility of operator damage due to recoil.

OUR BEST PRODUCTS TO SAVE ENERGY, INCREASE SAFETY AND EFFICIENCY!

Dynabrade Air Line Assembly, Spark-Resistant

Resistant to scorching and damage while exposed to sparks in welding or steel cutting environments.

Dynabrade Air Line Assembly, Antistatic

The electrically conductive hose is made of braided EPDM Rubber that dissipates electro-static discharge and minimizes errant sparks.

For more performance, combine these Air Line Assemblies with Dynabrade Tools!

After replacing ineffective hoses and removing leaking couplers, the next stage in the optimization process is to install the right product in the proper position! Tools and components that have the lowest possible pressure drop will put less strain on the compressor. And good news, Dynabrade Tools are perfect for that!