How and when to lubricate your tools?

Wondering how to maintain and lubricate your air tools? Discover all our recommendations here!

Pneumatic tools are tools powered by compressed air. They are often used in workshops, car body shops, construction sites, factories, etc…

These tools require special attention for their maintenance, this is where the secret of their longevity lies, since a well-maintained pneumatic tool has a much longer life than an electric tool. This is why they are appreciated and adopted by many professionals.

How to properly maintain your pneumatic tools

As we said, air tool maintenance is essential to prolong their life and ensure their proper functioning. Here are our tips on how to properly care for your air tools.

1. Clean air tools regularly.

Tool use areas are usually already dusty areas. Residue builds up during applications. Therefore, air tools should be cleaned regularly to remove and limit residue and dust that may accumulate inside. To do this, simply use a soft, dry cloth to wipe the outside of the tool.

2. Lubricate air tools regularly

It is important to regularly lubricate your air tools with air tool lubricants. This will reduce wear on moving parts and improve performance. You should lubricate your air tools before each use, especially if you use them for an extended period of time, or, you can use an FRL that will take care of lubricating your air by itself.

3. Store your tools well

To store your air tools, use storage boxes or bags to protect them from dirt, dust and moisture. Store your air tools in a dry place that is free from dust and moisture. You should as well avoid exposing your tools to extreme temperatures.

4. Take care of your tools

It goes without saying, but air tools can be damaged by falling or being mistreated. Avoid dropping your air tools or hitting them against hard surfaces.

How should you lubricate air tools?

Regular lubrication of air tools is important to extend their life and ensure proper operation. There are three Dynabrade maintenance solutions, here's how to use them to lubricate your air tools.

Dynabrade Air Lube

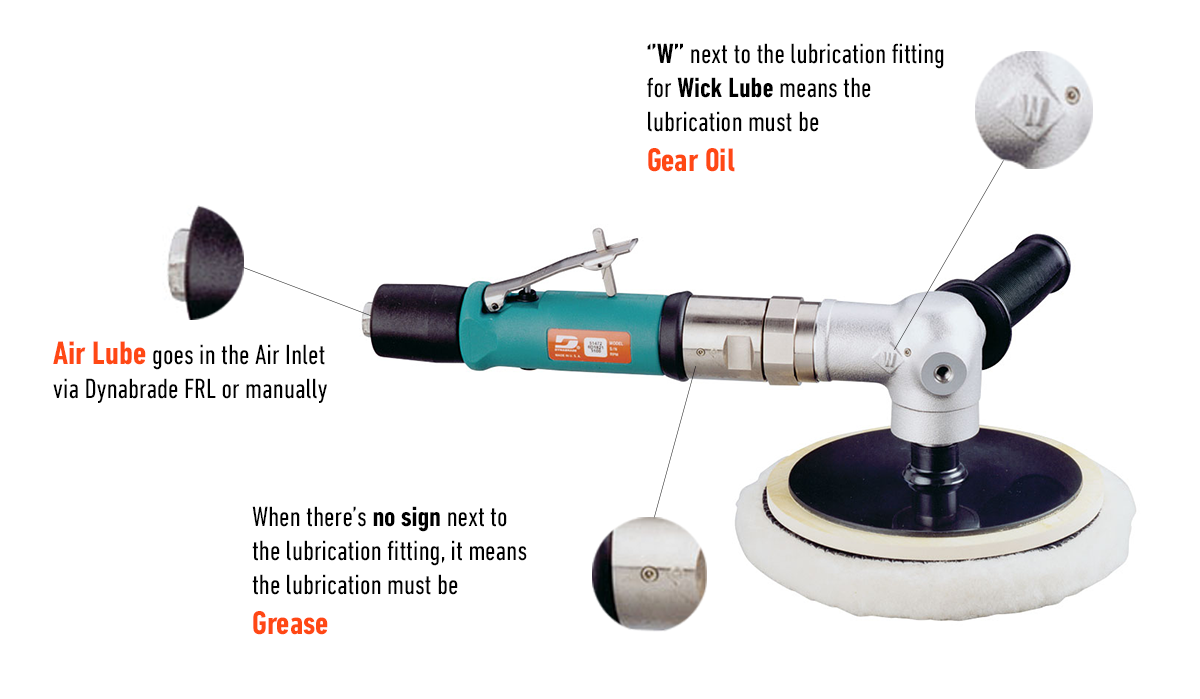

Air lube should be used on all tools (except Turbine Pencil Grinders). It is used through the Air Intlet manually or with a Dynabrade FRL (Filter - Regulator - Lubricator) system.

FRL

If you regularly use air tools, it is recommended to install a system like FRL since it automatically adds oil to the compressed air before it enters the air tool. This makes maintenance easier and ensures that the air is properly lubricated and filtered.

Gear Oil

To lubricate the gears of your air tools, use Dynabrade Gear Oil. Our Gear Oil is to be used only when a W is next to the lubrication fitting. It should be applied every 8 hours of operation to prevent premature gear failure. It can be used with the Dynabrade Grease/Oil Gun!

Grease

When there is no sign next to the lubrication fitting, you will need to use Dynabrade Grease. This is a multipurpose grease for all types of bearings, cams and gears. It has excellent resistance to water, steam, etc. and has high-film strength.

Here is a small illustration of how to properly lubricate your Dynabrade air tools:

Conclusion

Regular lubrication and maintenance of air tools is essential to ensure their proper operation and prolong their life. By following our tips, you can take care of your air tools efficiently and economically!